With few exceptions, the diamond-shaped bike frame has dominated since the early 20th century. But a couple of years ago, an aching back from cycling hundreds of miles got entrepreneur Lou Tortola of Windsor, Ontario, thinking about changing the design to make it more comfortable. “With the conventional frame geometry, the jarring vibrations from bumpy roads travel straight up the rear forks to the seat and the rider’s spine,” he says. “Bicycle companies have spent millions developing composites to reduce impact and increase shock absorption, but they haven’t changed the frame shape.”

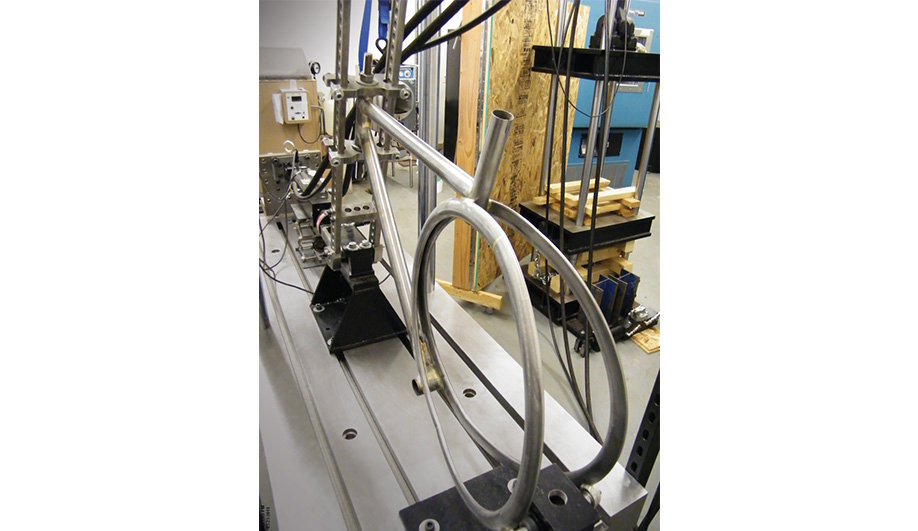

Tortola’s concept, which he developed in 2011, does away with the seat tube and stay – two rigid, straight elements that transmit vibrations directly to the base of the spine – and replaces them with a pair of tubular circles, to better absorb bumps without compromising performance or lateral rigidity. In just four months, he made his first prototype, the Roundtail, in collaboration with Montana frame builder Paul Taylor. At its launch during the

San Diego Custom Bicycle Show in April 2011, it set the frame-building world alight. “People loved it,” says Tortola. So he began full manufacture of the bikes, and started selling them online last summer.

Meanwhile, he has developed four new models, as well as an upcoming carbon fibre mountain bike, and has been in talks with European distributors. “Years ago, the diamond frame was the way to go, because of limitations in manufacturing ability,” says Tortola. “But today we can radically alter the design of a bike frame to produce a better, more comfortable ride for everyone.” roundtail.ca

Tristan Kopp, a Design Academy Eindhoven graduate, is also working on a unique approach to bike building. His Produser concept uses a kit of connector parts: five pairs of metal pieces that hold together the seven tubes of a diamond frame. It would enable DIYers to fashion a frame with almost any material, from bamboo branches to metal pipes salvaged from junkyards or used-bike stores.

The project has received some early praise on the web, though Kopp is still at work on raising funds and launching a website to take online orders by September. Yet he is already exploring ways to maximize the project’s social impact. “I want to organize workshops with children,” he says, “in collaboration with a recycling centre, so the kids can search through the waste for the parts they need and build their own bicycle.” tristankopp.com